Overview

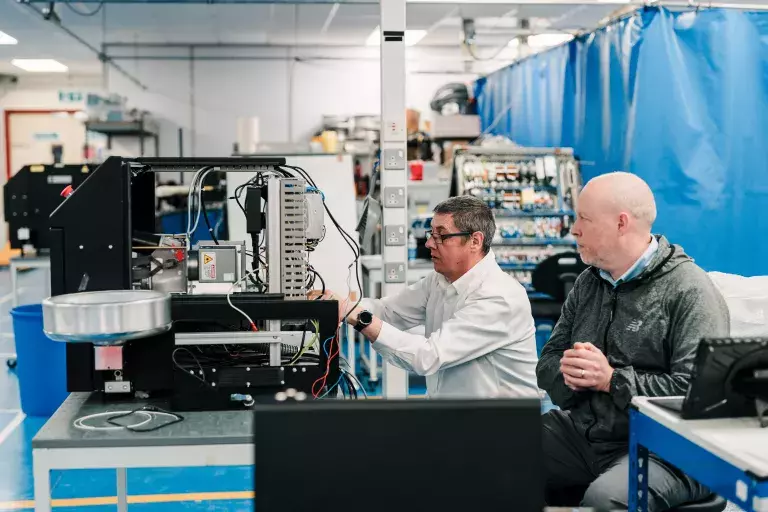

Nova MaX™: A high performance measure and cut to length system for processing a wide range of wire and cable types and sizes used in the production of complex electrical wire harnesses for aerospace, defence, military vehicles, rail and other specialist applications.

Nova MaX is a wire measure and cut to length system for processing wire and cable up to 15.6 mm / 0.6 inch outside diameter. The system has a PC control system for data management and job set up and options for integrated heat shrink sleeve and label printers. It offers a complete solution for preparing cut wire and cable.

Benifits

No need to work from hard copy wire lists any more: paperless job set up is enabled through the PC interface by means of the Windows based Nova programming software allowing easy scheduling of work. The PC can be networked for connection to your factory database. Job data may either be directly downloaded from a host connection or input via CD / DVD / Flash drive. When required wires and cables can also be easily set up and processed as single sections.

MaX is designed for ease of set up and simplicity of use. The system processes wires, measuring and cutting them to length while optionally simultaneously printing heat shrink sleeves and labels as required to create a mini kitting facility. A touchscreen monitor can also be supplied as an option.

The system may be used with a wire tree or single dereeling unit and can also be paired with different wire processing accessories to facilitate and speed up downstream processes.

Images

Technical Specifications

- Wire size range: up to 15.6 mm (0.61″) outside diameter

- Wire length accuracy: -0%/+0.5% (maximum)

- Maximum speed: 20 m/minute (65 ft/min)

- Bench-top system

- PC controlled with standard CAPRIS & Nova programming software – networkable and familiarity for existing Spectrum wire marking equipment owners

- “Wire Save Mode” for wire/cable above 3.8mm (0.15″) diameter – zero wire wastage at the start of each job

- Colour coded wire guides to make wire loading simple and easy, saving time on set up when processing many wire types

- Powerful pneumatic shear to ensure clean cutting and minimise deformation to wire ends – cuts through cables with high conductor densities that many other cutting machines cannot cut

- Software variable wire pull and acceleration for maintaining length accuracy and avoiding over-tensioning smaller gauge wires

- Option for integrating peripherals such as label printers, sleeve printers and a barcode reader for automated kitting facility

For more information