Overview

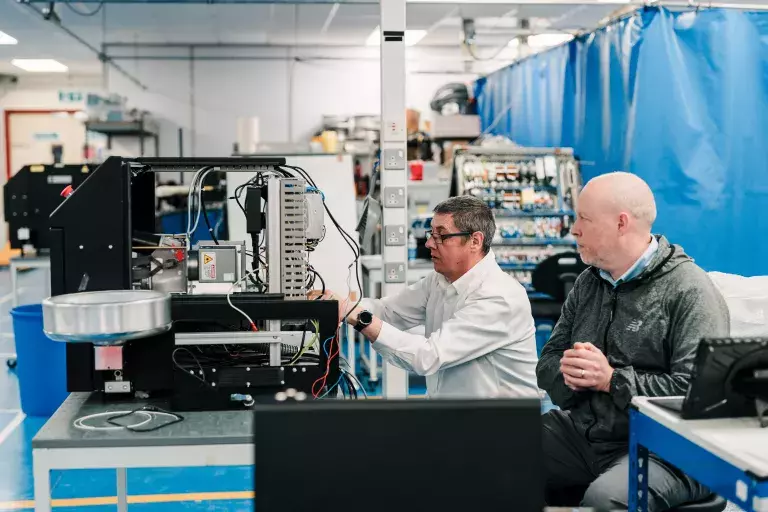

The Nova 800i series is an innovative, state-of-the-art family of laser wire processing systems. The 6th generation of Spectrum’s laser wire markers incorporate the latest leading edge technologies. It is designed to meet in full the demands of today’s growing laser wire marking industry by providing a cost effective and production enhancing solution for complex harness manufacturing applications. Three models available: Nova 840i, Nova 860i and Nova 880i.

Benifits

the Nova 880i is the fastest, highest performing, laser wire harness processing system in the world! It offers simplified maintenance with longer maintenance intervals.

the Nova 800i series offers a major improvement in the performance cost ratio and capabilities – the most cost effective products on the market with minimal consumable parts required.

the Nova 800i series are designed on a modular basis and are easily upgradable in the field to provide faster marking and/or fully automated wire handling systems that are able to process up to 36 different wires

the Nova 800i ASL system provides rapid wire changeover of wires that can be processed efficiently, automatically and then grouped by connector, in place of subsequent manual sorting. System beam setup time is reduced through software providing alignment within a Class 1 environment. Through a controlled reduction in laser readiness time, wire processing throughput is significantly increased.

The Nova 800i series through a combination of software and hardware design provides the customer with the option of a wide range of capabilities from character marking, system monitoring and performance traceability.

Images

Technical Specifications

- Three models available: Nova 840i, Nova 860i and Nova 880i.

- High performance Diode Pumped Solid State UV laser technology

- Direct write scanning character creation

- Knot and splice detection system

- Measure and cut capabilities for non-markable wires

- Manual or automated wire loading system

- Single powered coiling pan

- Processes 28 AWG – 6 AWG wires and cables, from 6″ (15cm) – 3,250 ft (999m)

- System upgradeable in the field to Nova 860i or Nova 880i standard and/or from manual to automated system configurations

- STANDARDS & QUALIFICATIONS

- SAE AS5649 and ASD EN4650 Wire and Cable Marking Process, UV Laser - Qualified to Boeing Standard D6-36911

- The laser marking process has been verified not to cause any impairment to the wire surface or to vary the electrical or mechanical properties of the wire insulation when carried out in accordance with the operating instructions

For more information