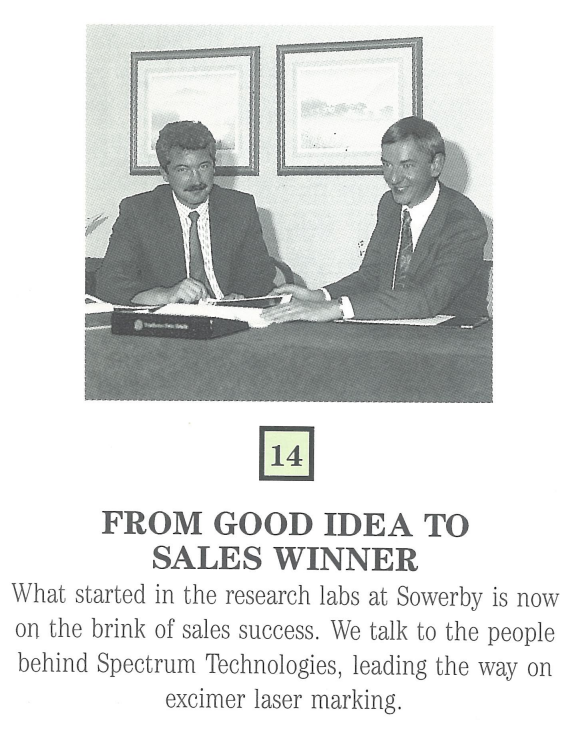

Following the discovery and development of ultraviolet (UV) laser wire marking in 1987/8 by the Optics and Laser Technology Department (OLT) at British Aerospace’s Sowerby Research Centre in Bristol, UK, discussions were held with British Aerospace (BAe) Enterprises in January 1989 on the commercialisation of the technology. In May, the McDonnell Douglas aircraft company in the US delivered a request for quote for an excimer (UV) laser wire marking system to OLT. As part of a research centre, OLT was unable to respond to such a commercial request and the bid was won by an American company, Vektronics Inc, based in California. However, the increased level of interest and demand from industry catalysed the situation and in August the British Aerospace Board of Directors approved the formation of Spectrum Technologies Ltd as a wholly owned subsidiary reporting to BAe Enterprises and in October Spectrum Technologies Ltd came into being. Peter Dickinson, who had led BAe’s industrial laser research programme at Sowerby, was appointed Spectrum’s Director and General Manager while Richard Hooke, New Projects Director at BAe Enterprises, became its Chairman.

Spectrum Technologies set up operations at its first home on the Science Park in Bridgend, Wales, UK, and started operations with 4 employees. The Rt Hon David Hunt, Secretary of State for Wales, officially opened the company’s new premises in September. In this year the first UV laser marked wiring harnesses for a production aircraft were manufactured on the BAe Filton machine, for the wings of an Airbus A320. Registered trade mark sign should be supersrcipt on CAPRIS. In the meantime, the Company In the meantime, the Company’s first product, the mask-based CAPRIS® 500 (C500) UV excimer laser wire marker was developed, based on the Filton prototype (CAPRIS – Cable Processing & Identification System). The CAPRIS 555 The C500 offered mark, measure and cut capabilities and was able to process wire and cable from 26 ga. up to 6 ga. (0.9mm to 6.25mm outside diameter) and was capable of marking a complete 16 character wire code with a single 20 ns laser pulse. The launch customer was British Aerospace Military Aircraft at Samlesbury, Lancashire, for use in the production of Tornado fighter aircraft harnesses. Throughout the early 1990s the team at Spectrum grew as it developed UV laser based products for other applications. These included systems for use in the manufacture of satellite components as well as medical applications.

Spectrum won its first export order from Boeing Commercial Airplane, Corinth, TX, USA for a C500 UV laser wire marker. Following this it received orders for two CAPRIS 555 (C555) UV laser wire markers. The C555 was a custom excimer laser wire marking system; it was developed for Airbus Hamburg, Germany, who became the launch customer in Europe, closely followed by Airbus Speyer, Germany. The C555 was the first wire marker to utilise a spinning mask, marking one character per laser pulse.

The CAPRIS 100 (C100) was Spectrum’s 2nd generation excimer laser marker developed as a derivative of the C555 model, with the launch customer being Smiths Industries (now GE Aerospace) based in Cheltenham, UK. Using the spinning mask allowed wire codes of over 100 characters to be marked, as well as allowing the code to be changed on the fly, enabling the marking of source/destination codes at wire ends as manufacturing aids. The C100 was exported globally and became the mainstay of harness production for the international aircraft industry through the second half of the 1990s and into the 2000s until replaced by later systems; it continued in use with some customers up to 2020.

Spectrum also continued with new developments of specialised UV laser technology, including laser etching of aluminised 2.3m (7.5ft) diameter Kevlar gridded, shaped Ku band microwave satellite antennae. These were a key component required for Orion 1, later renamed Telstar 11, Europe’s first communication satellite using laser etched, grid technology with shaped beam reflectors.

https://sky-brokers.com/satellite/telstar-11-orion-1-at-15-west-retired/

As British Aerospace restructured its businesses, the company was the subject of a management buyout in March 1994, with BAe retaining a 20% stake. Peter Dickinson was appointed Chairman and Managing Director, with Robert Briggs as Finance Director. During the year key orders were won from Westland Agusta Helicopters (now Leonardo) in Italy and from Boeing for multiple sites in the USA.

Export demand for its innovative products increased and Spectrum Technologies was proud to be a recipient of its first Queen’s Award for Export the UK’s top award for export achievement. To be a recipient of the Queen’s Award, a company must show a substantial and sustained increase in export earnings, to a level which is outstanding for the products and services concerned and for the size of the organisation. Spectrum has developed and sustained a strong export record over time, with typically 95% and greater of annual sales being for export.

CAPRIS 50

The CAPRIS 50 (C50) was introduced as the first of Spectrum’s 3rd generation UV laser wire markers. Importantly, it was the first low-cost, compact UV laser wire marker on the market, providing access to UV laser wire marking technology for aircraft maintenance, repair and overhaul (MRO) operations and low volume manufacturing applications. It was also the world’s first Neodymium (Nd:YAG) flash lamp pumped solid-state solid-state UV laser based wire marker, offering on-the-fly marking capability.

Kelowna Flightcraft (now KF Aerospace), based in Kelowna, British Columbia, Canada, purchased the first C50 UV laser wire marker. By the end of its production run in 2003 over 150 CAPRIS 50 units had been sold worldwide.

Spectrum scored its first export success in the Asia Pacific region with a C100 order for Mitsubishi Heavy Industries in Japan, for MHI’s Komaki Plant in Nagoya where it was used to assist in the manufacture of the SH-60J ASW Helicopter for the Japanese Navy.

Princess Anne visits Spectrum

During the year, Her Royal Highness Anne, The Princess Royal, visited Spectrum Technologies while in South Wales on an official visit and undertook a tour of the factory in recognition of Spectrum’s earlier Queen’s Award.

Spectrum established its first US office in Riverside, CA to provide sales and service support to the company’s North American customer base.

CAPRIS 60 launched

The CAPRIS 60 (C60), 3rd generation solid state UV laser system, was introduced as a mid-range laser wire marker. The launch customer was Kakamigahara Aero Equipment (KAE) located in Kakamigahara City, Japan.

As the new millennium dawned, the CAPRIS 50 (C50) laser wire marker was among the first designated Millennium Products, representing the very best of British innovation, creativity and design, selected under the nationwide initiative run by the UK Design Council.

Spectrum wins first order from South America

Spectrum Technologies received its first export order for South America from Embraer S.A, the Brazilian aircraft manufacturer and the third largest producer of civil aircraft after Airbus and Boeing. Multiple C60 systems were installed at Embraer’s Sao Jose dos Campos factory in Sao Paolo, to support manufacture of wire harnesses for the Embraer ERJ-135 and ERJ-145 regional jet aircraft.

During the year the company won three export awards, including its second Queen’s Award for Enterprise for International Trade. Spectrum Technologies also won the British Trade International Export Award for Smaller Businesses 2000, Welsh Region and was awarded the title of Exporter of the Year in an awards scheme coordinated by the Welsh National Assembly. Spectrum was the only company in Wales that year to receive a Queen’s Award for Enterprise for International Trade. The award was given following the Company’s high level of success in export markets during the previous three years during which export sales more than doubled.

First Minister opens new factory, as Lord Lt presents 2nd Queen's Award

As business expanded Spectrum Technologies moved to a new 20,000 sq.ft factory in Bridgend, UK. The First Minister of the National Assembly for Wales, the Rt. Hon. Rhodri Morgan, undertook the official opening of the Company’s new factory on 16 November 2000. The company also opened a new US Sales and Support office in Dallas, Fort Worth.

Following its own research into laser wire stripping, Spectrum Technologies acquired RtMc Inc Phoenix, AZ, USA, a manufacturer of laser wire stripping products. These were subsequently further developed and marketed as the SIENNA range. Spectrum also acquired the assets of its main competitor in the aerospace laser wire marking market, Vektronics Inc, of Vista, CA, USA. The downturn from the bursting of the dot.com bubble combined with the impact of 9/11 on the aerospace sector resulted in the necessity for a major restructuring of the company.

Following a development programme for a new range of wire markers using solid-state UV lasers, the company launched its new 4th generation CAPRIS 50-100 (C50-100) entry level and CAPRIS 50-300 (C50-300) mid-range laser wire markers. These products used the Company’s new proprietary state-of-the-art industrial Longbow flash lamp pumped solid-state Nd:YAG laser. The launch customer for the C50-100 was Aircraft Services Group (ASG) in Miami, FL USA.

As the business recovered from the effects of the 2001 downturn Spectrum Technologies USA Inc. relocated its US HQ to a new factory and offices in Phoenix, AZ. During the year, Spectrum delivered its last UV excimer gas laser wire marker, C100 #C100-66 to Airbus in Hamburg.

Spectrum topped off its new 4th generation range with the launch of the CAPRIS 60-200 (C60-200) high volume solid-state UV laser wire marking system, which was the fastest, highest performance, solid state UV laser wire marker in the world at that time. The system was able to be configured for either manual or automated wire loading. The launch customer was Westland Agusta Helicopters (now Leonardo), in Italy.

As the business continued to develop, the engineering and production of all SIENNA products was transferred from Phoenix, USA and consolidated into Spectrum’s Bridgend, UK operation. Following this Spectrum introduced the newly developed SIENNA 200 and 300 laser wire stripper models. The company relocated its US HQ to an expanded Dallas Fort Worth, TX facility. Spectrum Technologies Technologies USA Inc now provided focused sales and after sales support service to the Company’s North American customer base from its offices in Phoenix and Dallas/Fort Worth, Texas.

SIENNA laser wire strippers

The SIENNA 200 series dual beam laser wire strippers (pictured) are compact, bench-top systems suitable for processing the majority of wire types and insulation materials used in the manufacture of consumer and medical electronics. The launch customer was Foxconn in China. The SIENNA 300 series are higher power dual beam bench-top laser wire stripper systems, suitable for processing wire and cable with tougher, higher resistance insulation materials. The launch customer was Molex De Mexico. Spectrum Technologies also launched the innovative SIENNA 55ES compact rotary laser wire stripper targeted at the aerospace industry in 2006. On the back of the recovery and growth of its business since 2001, Spectrum was delighted to be the recipient of a third Queen’s Award for Enterprise for International Trade in 2006.

Maintaining its drive for innovation, Spectrum introduced the new Nova™ 880 ultra-high speed UV laser wire mark, measure and cut system as the lead in product for Spectrum’s 5th generation of laser wire markers. The system was officially unveiled in November at the Productronica show in Munich, Germany, with Sikorsky Helicopters as the launch customer.

Spectrum Technologies opened first Asia office

Spectrum Technologies opened its first Asia office in Hong Kong to provide sales and service to support the expanding customer base in Asia Pacific.

Spectrum continued the roll out of the new Nova series with the Nova 820, 840 and 860 models replacing the 4th generation C50-300, C50-300ES and C60-200 models.

Development of a new inkjet based wire marker, NovaJet, was initiated to meet the requirement of Sikorsky Helicopters for a solution to produce a permanent contrasting mark on black filter-line wire used in helicopters. NovaJet offered white ink marking with UV cure for enhanced permanence. The first automated NovaJet system was delivered to Sikorsky to replace an earlier custom inkjet wire marker developed by Spectrum for Sikorsky in the late 1990s.

Spectrum Technologies China relocates to Shanghai

A new sales office was opened in Shanghai, P. R. China to replace the Hong Kong office. The new location continued the Company’s expansion in the region as well as reinforcing its dedicated support network for customers in the region.

Spectrum Technologies USA Inc moved to a new larger facility in Fort Worth, TX to support the continuing growth of the company’s North American operations. The new facility was also able to offer Advanced Laser Maintenance training courses in the USA for the first time, enabling customers to benefit from tailored training packages to meet their specific laser system training requirements for their in-house maintenance technicians.

In May Spectrum launched the SIENNA 700 series, the company’s new top-of-the-range, high speed, high specification laser wire strippers, at the Electrical Wire Processing Technology Expo in Milwaukee, WI, USA. The new SIENNA 700 range was designed for precision-critical applications including medical device manufacture such as ultrasound cable assemblies and medical probes. The expanded SIENNA laser wire stripper range, encompassing the new SIENNA 600, 700 and 800 models, was introduced at the Productronica exhibition in Munich, Germany in November. The new SIENNA 600 and 800 models aimed at high volume, high precision electronic manufacturing applications.

The C50-100, reached sales of 250 units following receipt of an order from Boeing Aviation Services, Shanghai, China.

Spectrum Technologies’ Shanghai branch office moved to new larger premises to accommodate the growing demands of this increasingly important region for aerospace manufacturing as well as its established electronics manufacturing industry. The larger office is able to stock key spare parts for CAPRIS and Nova laser wire marking systems to support customers in the region better.

Spectrum’s new SIENNA 900 Laser Magnet Wire Stripping system was unveiled at CWIEME in Berlin. The SIENNA 900 utilised dual wavelength infrared lasers to strip hard enamel from magnet wire for motor and alternator windings.

Spectrum won a key order to supply the new SAIFEI Joint Venture between Safran and Shanghai Aircraft Manufacturing Co., Ltd. (SAMC), a subsidiary of the Commercial Aircraft Corporation of China (COMAC) in China with a Nova 860 high speed UV laser wire marking and processing system. The system was delivered later in the year to SAIFEI’s new facility in Pudong, Shanghai, China to support commercial aircraft programmes, including the C919 jetliner.

Spectrum made its first major entrée to the rail sector with an order from Bombardier Transport North America for a Nova 860 high speed UV laser wire marker. The system was installed in their 1.2 million sq.ft. manufacturing plant in Mexico for use in the production of the electrical wiring systems for a major project to supply new rail cars for the San Francisco Bay Area Rapid Transport (BART).

Nova 1000 launched

Spectrum launched the Nova 1000 at the Wire China show in Shanghai. The Nova 1000 is a high performance UV laser system designed for integration into wire and cable production lines to meet wire manufacturers’ needs for in-line laser coding of difficult to mark insulations. It was the company’s first laser wire marker to utilise diode pumped solid-state (dpss) lasers combined with scanning galvanometers.

Volkswagen orders SIENNA 900

Spectrum received an order from Volkswagen AG, Germany for the first of two SIENNA 900 magnet wire stripping systems. The technology was chosen for integration with a new manufacturing line producing electric motors for the VW Golf GTE and Audi A3 e-tron hybrid vehicles.

Following extended research into diode pumped solid-state UV lasers, Spectrum Technologies launched the new, 6th generation Nova 800i Series of UV laser wire marking systems. The Nova 800i series introduced air cooled diode pumped, all solid-state lasers combined with galvanometric scanning systems in an innovative, state-of-the-art family of laser wire processing systems, comprising three models: the Nova 840i, 860i and 880i. These replaced the equivalent Nova 800 series mask based models, while offering improved performance.

Spectrum wins local business awards

Spectrum Technologies was pleased to win two awards at the regional Bridgend Business Awards. Hosted by the Bridgend Business Forum, Spectrum was shortlisted for the ‘Innovative Business of the Year’ category and went on to be named the winner. Following the success in this category, Spectrum also received the Patron’s Commendation Award. Presented by the First Minister of Wales, the Right Hon. Carwyn Jones Hon. Carwyn Jones AM, he noted Spectrum’s contribution to the local area for over 25 years, support of the local supply chain and multiple Queen’s Awards for Export.

Following on from the launch of the Nova 800i series the new 6th generation entry level Nova 50-100i Series UV laser wire marking systems debuted at Productronica in Munich, Germany. The Nova 50-100i series completed the line-up of diode pumped all solid-state lasers with galvanometric scanning systems with a new, state-of-the-art family of entry level to mid range laser wire processing systems. The range comprises three models: the Nova 50-101i, 102i and 103i, which replaced the CAPRIS 50-100, and the Nova 800 and Nova 820.

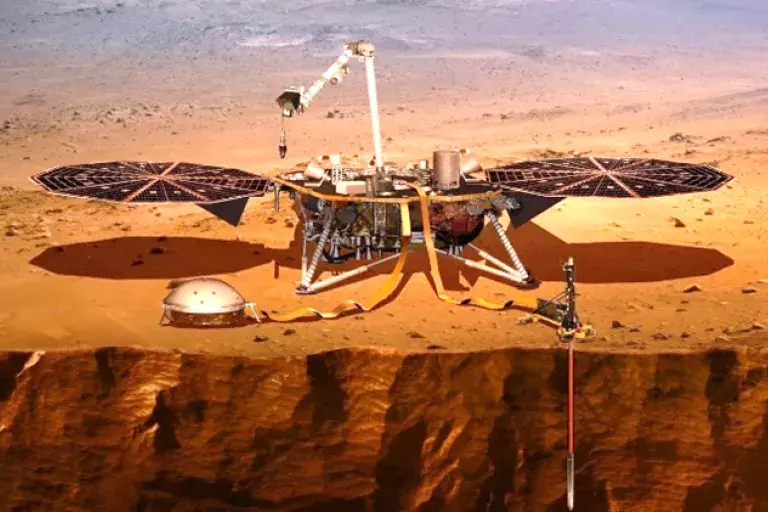

On 26 November 2018 the NASA InSight probe touched down on the Red Planet. InSight, short for Interior Exploration using Seismic Investigations, Geodesy and Heat Transport, set out to study the deep interior of Mars. The electrical wiring interconnect system (EWIS) for InSight was manufactured by Lockheed Martin Space in Denver, CO, USA using a Nova 820 UV laser wire marking system.

SIENNA 1000 announced

Spectrum Technologies announced its latest product release SIENNA 1000 – a state-of-the-art new laser stripper. The SIENNA 1000 has been designed with the ability to integrate different laser types according to the customer’s application. Applications include stripping (skinning) of enamelled copper wire, wound components, bonded polymer-based insulations, braided wire and various plastic and metallic components.

Spectrum reached a milestone with the 30th anniversary of its establishment on 14th October, having supplied over 1000 laser wire marking systems to customers in nearly 60 countries on 6 continents, making it unquestionably the world market leader in the development, manufacture and supply of UV laser wire marking equipment. The company was again awarded the title Innovative Business of the Year at the Bridgend Business Forum Awards 2019.

Spectrum Technologies USA Inc moved to a new unit in Haltom City, Fort Worth, TX, providing larger, improved repair, overhaul and training facilities.

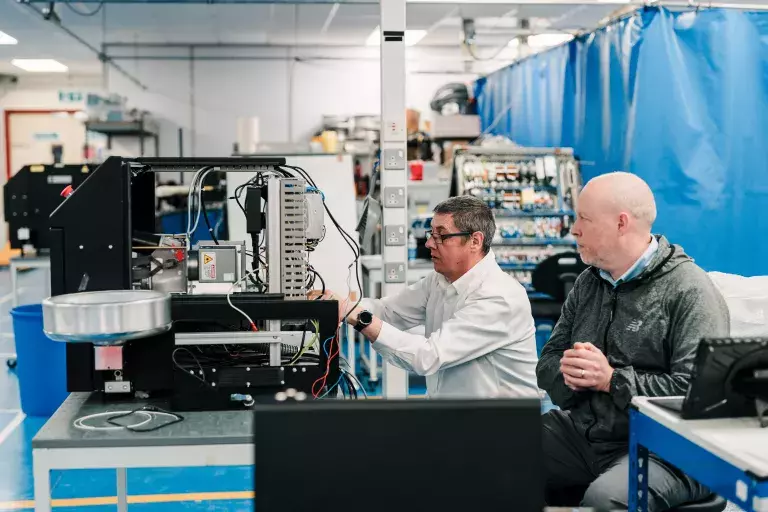

Following a faster than expected post-covid recovery in business, starting from mid-2022 the company largely completed rebuilding, with staff levels recovered to pre-pandemic levels during 2023. This included the appointment of a new senior management team. A programme of major enhancements to legacy products and new product developments aimed at diversification were initiated.

Following a meteoric recovery in business from the covid low of 2021, sales reached a record level in March 2024 having more than doubled to over £10M, with exports reaching £9.95M. As a consequence of this rapid growth in exports over the previous three years, Spectrum Technologies Ltd was delighted to be the recipient of its first King's Award for Enterprise for International Trade. By March 2025, sales has increased further to a new high of £11.26M, with exports rising to £10.83M.

Over 1,300 and counting laser wire marking systems have been delivered to date and installed with customers in 60 countries on 6 continents. At any time there are over 1,000,000 miles of laser marked wiring in the air, in around 12,000 commercial aircraft as they circle the planet. Spectrum Technologies continues to innovate and develop new products and disruptive manufacturing technology for existing and new markets.

Explore our diverse range of applications and discover how our innovative solutions can meet your unique needs.

Stay informed with the latest news and events from Spectrum Technologies. Discover updates, industry insights, and upcoming events.