SIENNA™ Laser Wire Strippers:

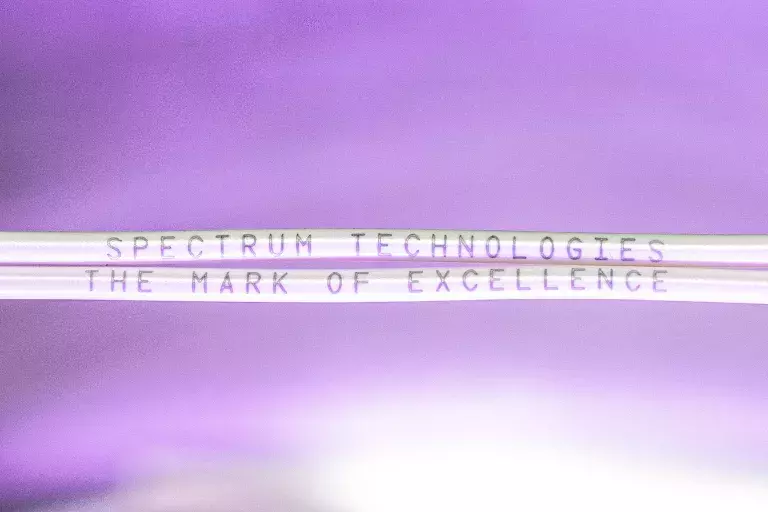

Damage-Free, High-Quality Wire Stripping

No Blades – No Nicks – No Damage

Spectrum Technologies’ SIENNA laser wire strippers offer cost-effective, high-quality damage-free stripping of hi-tech wire and cable constructions used in the most demanding manufacturing applications, including medical electronics, aerospace, consumer electronics and automotive.

Spectrum offers a range of SIENNA laser wire stripper products designed to deal with different wire types and manufacturing requirements, and developed to meet the requirements of a wide range of electrical manufacturing applications.

Each SIENNA family has different process capabilities and speeds, offering flexibility for differing production requirements and strip applications.

Providing the optimum laser wire solutions- whatever your application- from the original developers of laser wire stripping technology.

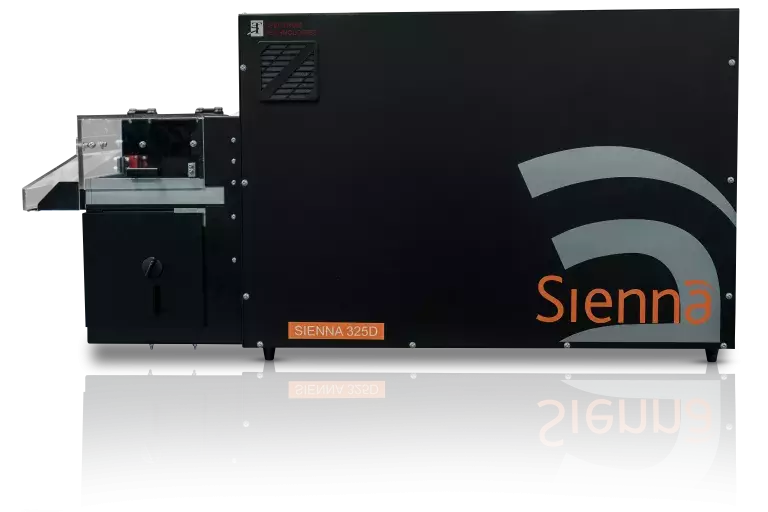

- SIENNA 200 series– Entry-level, linear laser wire strippers for general purpose wire stripping. Available in single axis (x or y), dual axis (x-y), or fixed beam configurations.

- SIENNA 300 series– A higher power version of the SIENNA 200 series with higher laser powers for penetrating tougher insulation types. Available in single or dual axis configurations.

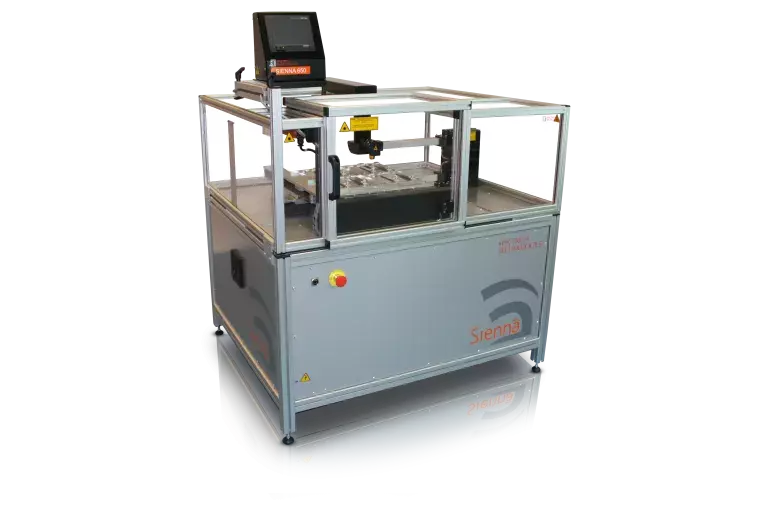

- SIENNA 500 series– Rotary laser wire strippers enabling complete 360 degree stripping on larger gauge wire and cable.

- SIENNA 600 series - The SIENNA 600 series is a range of fixed-beam laser wire strippers with a high speed dual axis stage designed for high throughput applications.

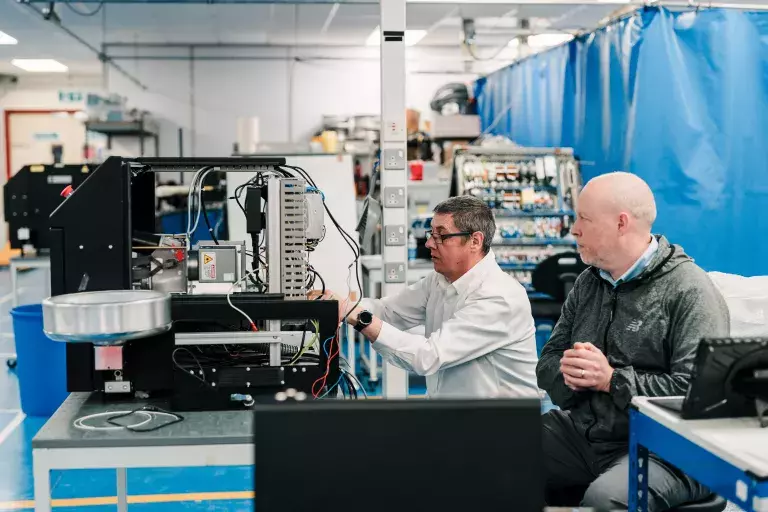

If you are unsure which SIENNA system is best suited to your application we would be very happy to process your samples in our lab and make recommendations.

For a more detailed discussion of laser wire stripping; including its development and the wire types with which it may be used, please see our Laser Wire Stripping Technology page.

AVAILABLE MODELS