Overview

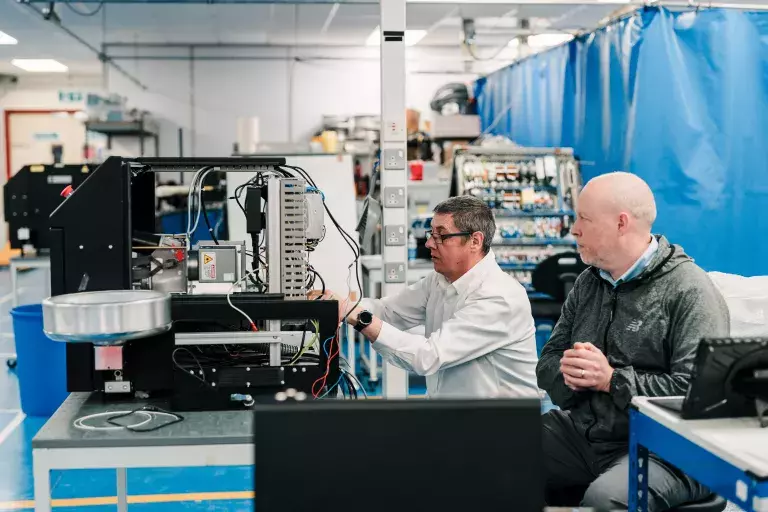

A range of wire and cable dereeler systems is available for interfacing with Nova laser markers. This includes single- and multi- station high specification powered dereelers, as well as more basic units.

Nova powered dereelers have been developed for controlled high speed dereeling to match the capabilities of Nova laser markers. Only powered dereelers fully meet the need for high acceleration and deceleration required to maximise throughput and productivity with high speed wire markers, while also limiting the tension applied to wires and cables.

CAPRIS and Nova laser markers and powered dereelers limit the load applied to wires by means of a controlled programmable tension which can be set as low as 10 Newtons. This avoids over tensioning and consequent problems of wire deformation or breakage.

Powered dereeler stations are fitted with a dancer arm and pulley arrangement through which wires are fed. As the wire is taken up by the laser marker, the dancer arm engages the dereeler motor which pays off the wire in synchronisation with the demand from the marker unit. The provision of back tensioning ensures that wires are correctly tensioned and that the pay off from dereeler stations is correctly synchronised at all times, including during rapid deceleration, thus avoiding problems of reels over running and resultant ‘bird nesting’ of the wire.

Nova single and multi-station dereelers provide completely enclosed dereeler stations to prevent operator access to rotating machinery. Interlocked doors allow operators access to change and set up reels, while preventing the possibility of operator access to live stations. This feature allows operators to safely reload stations on the D500EM while another station on the dereeler is active.

Technical Specifications

Nova D1 – Single Station Dereeler

A high specification system, CAPRIS Nova D1 single station dereelers feature:

- Rugged heavy duty design for maximum reliability

- Powered high speed dereeling up to 150 m/min. (500 ft/min.)

- DC motor driven pay off, synchronised to the demand from CAPRIS and Nova laser marking modules

- Controlled wire tension

- Interlocked safety enclosures

- Quick release mechanism for fast reel changeover

- Auto reverse – automatically rewinds wires at changeover

- 35 mm (1.40 inch) minimum wire bend radius

- 25 mm (0.98 inch) diameter dereeler spindle – adaptors available to accommodate other reel centre hole diameters

- Single phase operation via the main laser marking unit

- Accommodates reels up to 390 mm (16 inch) OD, 317 mm (12.5 inch width), 20 kg (44 lbs) weight

CAPRIS Nova D2 to D36 – Multi-Station Dereelers

CAPRIS Nova multi-station dereelers can be specified with a variable number of dereeler stations to meet customer requirements (the number in the product code corresponding to number of dereeling stations). For large numbers of stations, units may be configured with dereelers in two or three banks (vertically) and with two dereeler units back to back to minimise the system footprint.

Multi station dereelers provide users with the capability to set up the marking system with a large number of commonly used wires and cables. This reduces machine set up times for manual wire selection and loading. For maximum levels of automation and productivity, CAPRIS Nova dereelers can be interfaced with CAPRIS Nova ASL: wire Auto Select and Loading system for fully automated selection and loading of wires.

CAPRIS multi-station dereelers are controlled by a programmable logic controller. This senses which station is required for dereeling and energises only that particular station.

- From two to 32 stations at customers option

- Rugged heavy duty design with dereeler stations independently powered for maximum reliability and availability

- Powered high speed dereeling up to 150 m/min. (500 ft/min)

- DC Motor driven pay off, synchronized to the demand from CAPRIS laser marking modules

- Controlled wire tension

- Interlocked safety enclosures

- Auto reverse – automatically rewinds wires at changeover

- Quick release mechanism for fast reel changeover

- 25 mm (0.98 inch) diameter dereeler spindle – adaptors available to accommodate other reel center hole diameters

- 35 mm (1.40 inch) minimum wire bend radius

- Compact units with minimum footprint

- Single phase operation via the main laser marking unit

- Accommodates reels up to 390 mm (16 inch) OD, 317 mm (12.5 inch width), 20 kg (44 lbs) weight

For more information