Overview

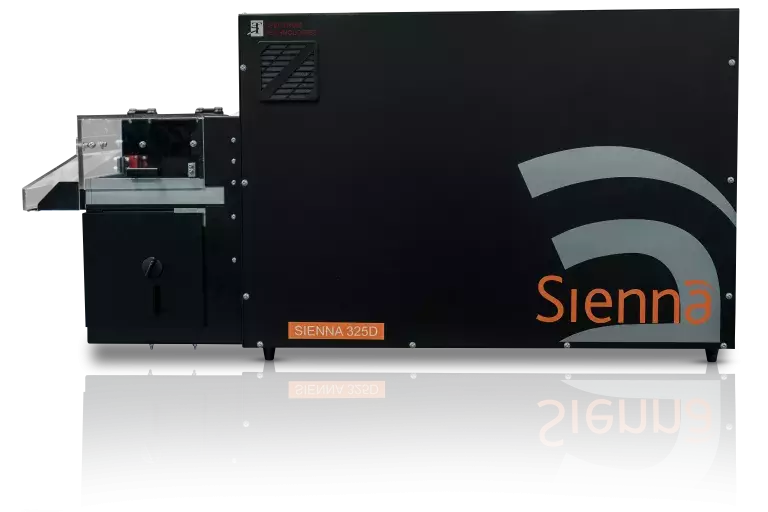

The SIENNA 300 series laser wire stripping system is a higher powered version of the 200 series for industrial applications requiring stripping of wire and cable with heavier insulations, and are also ideal for stripping fiberglass and cloth insulations where higher powered lasers are required.

The SIENNA 300 is a compact, bench-top unit dual axis wire stripper enabling complex strip patterns to be completed at any point along the length of the wire or cable. This capability allows the machine to perform a cross-cut and slit operation to aid slug removal and window strips to form terminations in the centre of the wire or cable. The standard scan area is 100 mm x 100 mm (4 inch x 4 inch). The SIENNA 300 also has the flexibility to adapt to a wide variety of wire and cable sizes and shapes with the added ability to strip both common and complex wire insulators.

Benifits

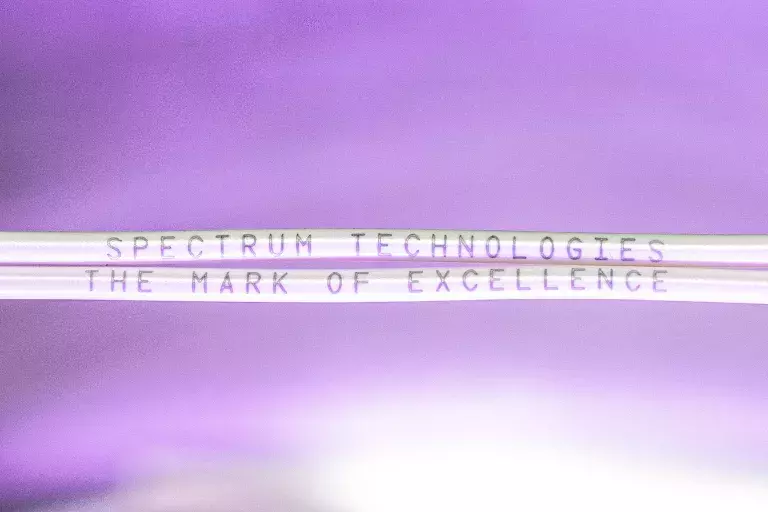

High quality and damage-free - the laser is reflected off the conductor, plating, or other metallic surfaces

Easy and clean stripping of tough insulation materials

Accurate

Repeatable

One machine for all wire configurations - single wire, twisted pairs, coaxial and ribbon cables

Processes multiple wires or cables simultaneously

Laser strips high temperature, hard or soft insulation materials effectively

End strips, window strips and other patterns easily performed in one operation

Increased job storage on dual axis versions with to PC software

Higher power laser options

All SIENNA systems are Class 1 laser products for use on open shop floor, unless otherwise stated

Complies to CAT 3 electrical safety category and all CE marking and FDA regulations

Images

Technical Specifications

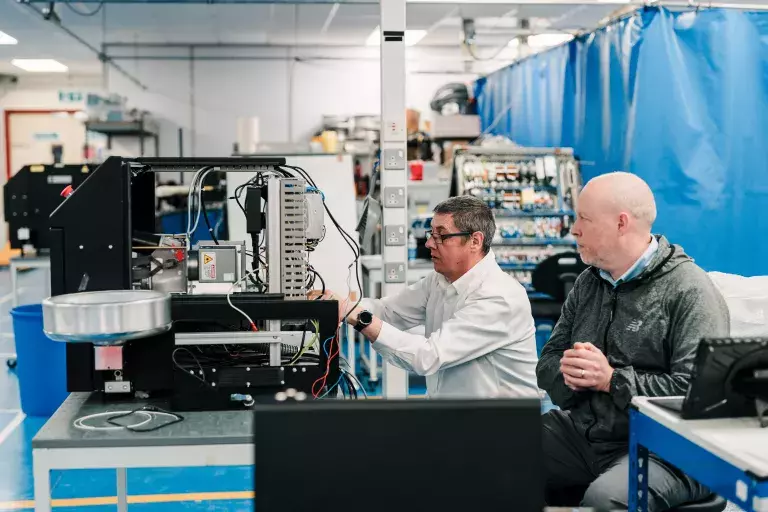

The systems are easily programmed via the front panel keypads; however a computer software interface is also provided which allows for programming via a PC, thus enabling a large number of wire file programs to be created and stored.

- Processes multiple wires or cables simultaneously

- Laser strips high temperature, hard or soft insulation materials

- Performs end strips and cross cuts (and windows and patterns with PC controlled dual axis system)

- Single wire

- Twin lead

- Twisted pairs

- Coaxial

- Ribbon cables

One set of universal tooling to accommodate a popular range of flat and round wire styles is provided with the machines. Multiple wire cables can be stripped through the use of tooling that accepts as many cables as will fit within the field of the beam motion.

Typical patterns that can be programmed are:

- Crosscuts

- Slits

- Windows

- Rasters

Windows are the removal of a section of insulation from a single wire or a group of wires anywhere along it’s length. They can be sized and placed to encompass one or more wires, and can also remove the insulation between wires.

The SIENNA 300 series wire strippers are available with flexible options for laser powers of 25 or 50 Watts to meet the requirements for varying process rates and differing production requirements.

For more information