Overview

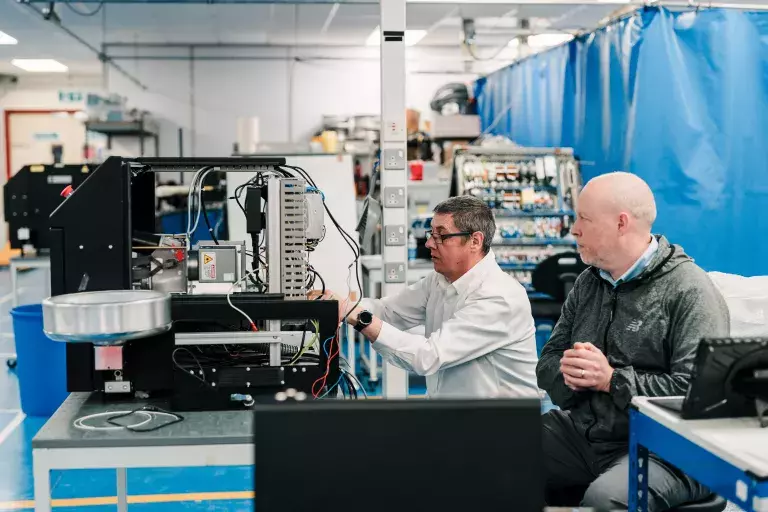

The SIENNA 200 series are entry-level laser wire stripping systems, available in both single and dual axis stripping configurations and suitable for most industrial applications requiring stripping of fine gauge wire and cable.

They are particularly suitable for stripping very fine gauge micro coaxial wires and ribbon cables used in the high volume production of computer inter-connect, mobile phone and other electronics applications.

The machines are compact bench-top units designed for flexible manufacturing applications. They provide the high quality and repeatable insulation stripping of a wide variety of wire types, sizes and configurations.

The SIENNA 200 series comprises 4 models:

- SIENNA 210S – single axis, 10 Watt laser

- SIENNA 210D – dual axis, 10 Watt laser

- SIENNA 220SRS – single axis, 20 Watt laser (Class 1 system)

- SIENNA 220SRD – dual axis, 20 Watt laser (Class 1 system)

Process rates vary accordingly, offering flexibility for differing production requirements.

Benifits

High quality and damage-free - the laser is reflected off the conductor, plating, or other metallic surfaces

Accurate

Repeatable

One machine for all wire configurations - single wire, twisted pairs, coaxial and ribbon cables

Processes multiple wires or cables simultaneously

Laser strips high temperature, hard or soft insulation materials effectively

End strips, window strips and other patterns easily performed in one operation

Images

Technical Specifications

SIENNA 210S

The SIENNA 210S is a single axis system with a scan area (stripping area) of 100 mm (4 inches), suitable for end stripping a wide variety of wire and cable types. Both ribbon cables and single core wires can be stripped; single core wires may be grouped and stripped simultaneously in batches within the scan area to maximise productivity.

Single axis system can only perform cross cuts for stripping cable ends.

SIENNA 210D

The SIENNA 210D is a dual axis CO2 laser system that provides a higher level of functionality – moving the laser beam in two directions, thus giving two axes of movement. this additional capability allows the machine to perform a cross-cut and slit operation to aid slug removal and window strips to form terminations in the centre of the wire or cable. The standard scan area is 100mm x 100mm (4 inch x 4 inch).

The SIENNA 210D also has the flexibility to adapt to a variety of wire and cable sizes and shapes with the added ability to strip both common and complex wire insulators.

Both systems are easily programmed via the front panel keypads; however a computer software interface is also provided which allows for programming via a PC, thus enabling a large number of wire file programs to be created and stored.

Strips various wire configurations such as:

- Single wire

- Twin lead

- Twisted pairs

- Coaxial

- Ribbon cables

- Multiple wires or cables simultaneously

Dual axis systems are capable of performing cross cuts and slits allowing window strips and patterns programmed via the PC software.

SIENNA 220SR

The SIENNA 220SR can be configured in a single or dual axis motion system. This laser system is for cutting shields on micro- and pico-coaxial cables.

Air Extraction

To comply with health and safety requirements, air exhaust must be provided when using any laser wire stripper. If this is not available in your factory, Spectrum’s ACS-5 systems remove all smoke, odours, particles and fumes from the laser stripping area and return clean air to the room

If you are unsure which SIENNA system is best suited to your application we would be very happy to process your samples in our lab and make recommendations.

For more information